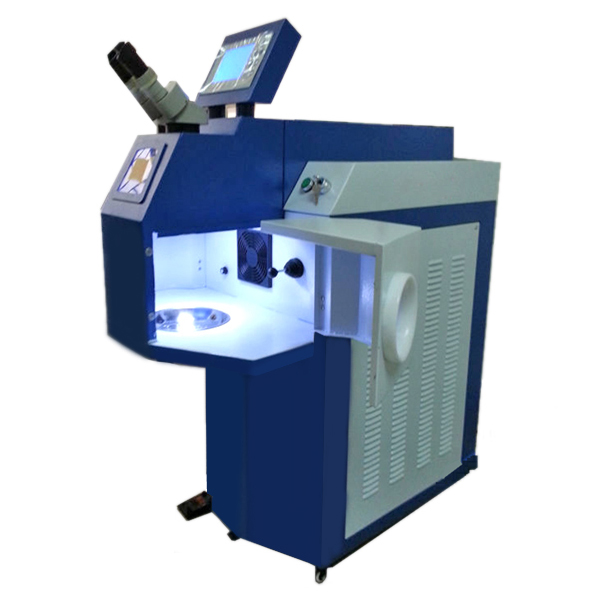

Description

The shape of welding

point, circle, arc and square, etc.

Machine warranty

Machine warranty: Two years warranty is provided.

Our benefits compared with others

After you receive machine, if our machine can not perfectly do your work or it is not the exact machine we have shown you during 3 months, we accept termless return.

After service

1.24/7 service is available to each customer. And if any technical questions or problems, our engineers will help you and give you solutions on the phone or by face-to-face communication online.

2.Professional staff for installation and training if needed.

Application materials

Suitable for many kinds mould steel material such as SKD-11,8407,718,738,NAK80,S136,W302,P20,2344,H13,A2,also copper, aluminum, stainless steel, jewelry, gold, silver etc metal materials.

Application Industry

This device not only serves as the special packaging equipment of battery production, but also can be used in the welding of metal materials, such as relay, sensor and various electronic components, etc.

The features of fiber equipment

It is specific Specifically for the mold making industry, instead of the traditional welding, soldering small heat affected area, does not lead to mold deformation, melt fully, repair firm, leaving no traces of repair, but no bump phenomenon, repair rate, especially suitable for polishing requirements mold repair.

Welding has high energy, compared to the general, easily fusible thicker wire welder, welding stable performance;

Single laser pulse, waveform can be adjusted to meet the complex requirements of the welding process special materials;

touch-screen interface, easy and friendly operation using the world’s most advanced automatic shading system, eliminating the time at work to stimulate the eyes.

the laser head can be rotated 360 degrees, the overall optical path part can rotate 360 degrees, as well as up and down electric lift, push around, especially for a variety of large, medium and small patches of mold.

parameter adjustment using intelligent remote control, simple operation and fast.

electric lift table can be three-dimensional movement.

electrically adjustable spot size.

Both manual welding and automatic mass production are available.

Machine Feature

1.High welding energy,thicker welding wire andmore stable welding performance than general welders.

2.Single laser pulse, the wavelength can be adjusted to meet the welding requirements of complex and special materials.

3.Touch screen interface, intuitive and convenient operation.

4.Ceramic converging cavity is imported from the Britain. It is corrosion resistant and high temperature resistant, and has 8-10 years service life. The life of xenon lamp is more than

8 million times.

5.Use the most advanced light shielding system to eliminate the irritation to eyes by light during working.

6.The laser head and optics part can be rotated for 360°,upward/downward lifting and

forward/backward pushing, suitable for repairing of large, medium and small moulds.

7.The parameters are controlled by intelligent remote controller, which is simple and

convenient.

8.The work bench can be lifted, and moved in three dimensions.

9.The size of light spot can be adjusted.

Application

It is suitable for repairing all kinds of molds such as precision injection molding, die casting

and all kinds of metal structures, gold, silver jewelry welding.

Reviews

There are no reviews yet.